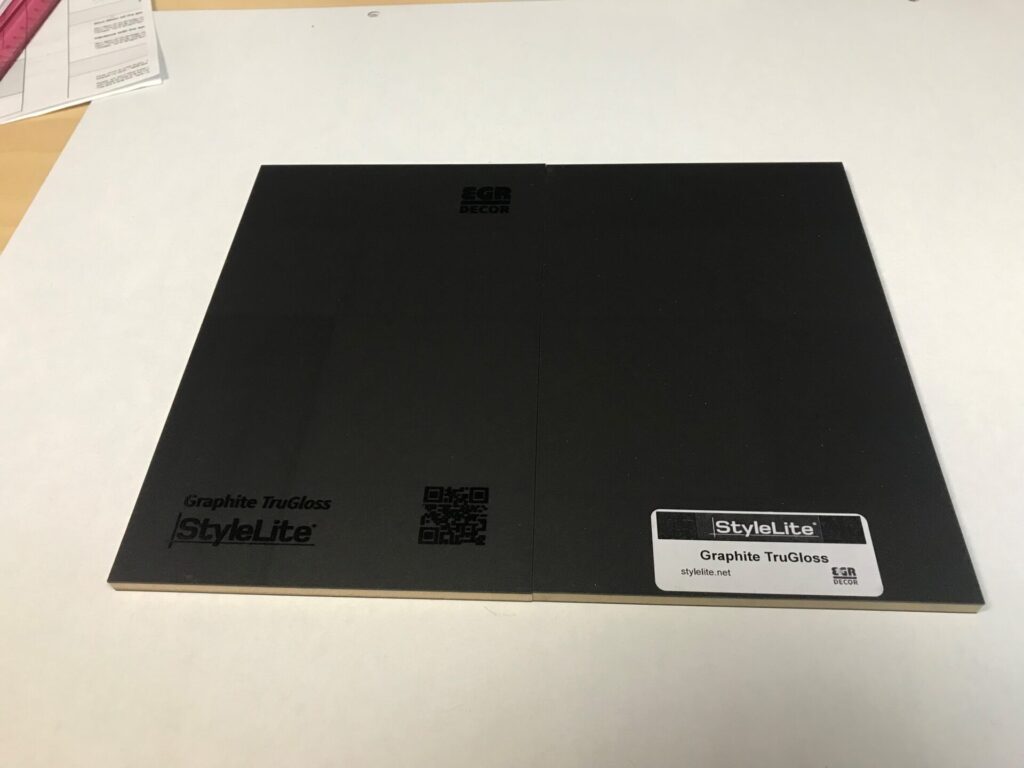

Peterman Lumber is now a distributor of StyleLite Laminate and Panels. We are thrilled to add this line to our offerings as a coordinated material with exact matching Panel, Laminate, Edgebanding and Made-to-Order Doors.

StyleLite not only rounds out our color options in our High Gloss and Super Matte textures, but it also has additional features inherent to the materials it is made of.

In this post, we will discuss the many benefits of StyleLite, as well as the information you need to purchase StyleLite products from us at Peterman Lumber.

Table of contents

The Benefits of StyleLite: Why It’s Right for You

StyleLite offers many advantages, including workability, superior finishes, repairability, and more. Below, we go through each advantage to show why you should consider these products for your next project:

Thermoformability & Workability

One of the features of an acrylic panel is that it is neither brittle nor made under pressure like materials like HPL or TFL. Additionally, it can be warmed up and miterfolded into shaker doors, floating shelves, or endpanels. In truth, StyleLite materials are all acrylic PMMA (transparent thermoplastic) capped ABS (another thermoplastic with fantastic mechanical properties) that result in an extremely workable surface.

It may sound complicated, but the combination of these materials gives it a high resistance to chipping and cracking, at the same time giving it the malleability to be thermoformed. Because it is not a brittle material, it is extremely easy to cut and highly unlikely to chip – even if bumped with pots and pans.

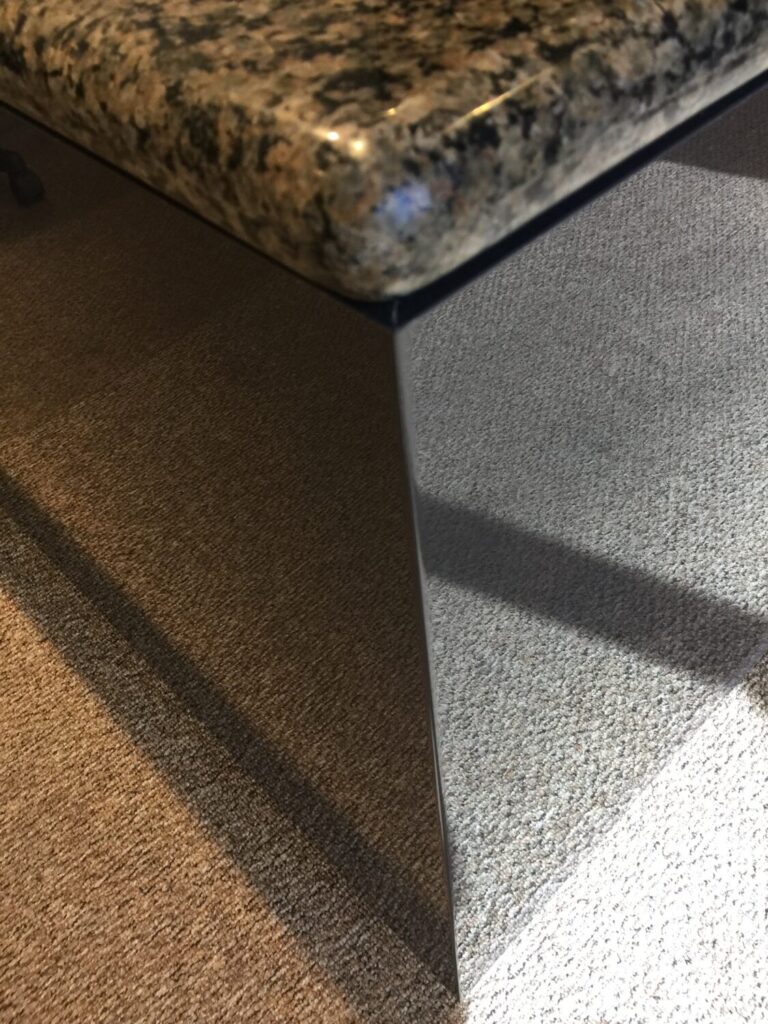

Superior Finish

Did you know that StyleLite takes a great deal of knowledge from the automotive industry? They are a branch of EGR, an industry leader in automotive accessories. One thing Stylelite takes seriously is a superior finish. In cars, if the finish doesn’t match it is noticeably different and no good. From this StyleLite shared 4 principles that you need to have for a superior finish.

- Thickness and flatness of laminate: StyleLite Panels are fabricated using the same extruded laminate sheets. Stylelite Laminate is 1mm and 43% thicker than other acrylic products in the market. 1mm is thick enough to eliminate telegraphing while also keeping them at a competitive price.

- Flatness of substrate: StyleLite uses a calibrated MDF core to ensure flatness and smoothness. If what you are laminating to isn’t flat, it doesn’t matter how flat your laminate is.

- Thickness of glueline: StyleLite uses 2,000nths of 1 inch of polyurethane (PUR) glue. Only a thin amount of this is needed for a strong and waterproof hold. The small even application between laminate and substrate avoids telegraphing/rippling of the surface.

- Clean environment: Stylelite has a dedicated cleanroom to laminate panels. This actually makes a big difference as it does not allow sawdust or debris to land in between the laminate and substrate.

PUR Adhesives

Knowing your types of adhesives is valuable especially when it comes to cabinetry meant for kitchens and bathrooms. Stylelite uses PUR adhesives for their panels that is a reactant glue that sets like concrete and unaffected by heat. It will not delaminate around heat producing appliances like ovens and dishwashers. Opposed to reactivatable (hot melt) glues that will turn back into a liquid state when exposed to heat. Peterman Lumber also uses PUR glue for our door fabrication for the same waterproof and heat resistant bond.

Repairability of TruGloss

One of the top concerns with any high gloss material is how well it holds up to scratches. StyleLite is the only high gloss material that is repairable. The high gloss is formulated with a high performance, 3-layer extrusion that gives it an amazing depth, and a surface that can be repaired. Peterman stocks a 3-in-1 Repair kit that will gently polish away surface scratches and keep it looking good for years.

Another way to help protect and clean the surface of StyleLite products is to use Vuplex Hardener (also available at Peterman Lumber). It is an antistatic for when peel coat layer is removed, but it is also a cleaner that helps to cure and harden the surface.

Metallics

One trend we are starting to see more of in the market is Metallics.

Metallics in the decorative surfaces is a tricky one to replicate because it must have similar woodworking to other panel products. It slows production in shops to change out blades and bits, especially if people didn’t know they needed to swap out for different blades and bits.

StyleLite has a gorgeous line of Metallic finishes that has more of an all over sparkle appearance in contrast to many of the brushed finishes we see in the market with the same ease of fabrication of the rest of their line.

Stylelite has 4 Metallic colors all available in TruGloss High Gloss, and Graphite that is also available in TruMatte.

Some customers are confused as to why StyleLite has arrows on their peelcoat. At a first look, you would assume that this is a solid color with metallic flakes. Nevertheless, it is a directional product and reflects light more in one direction than another. The arrows on the peelcoat ensure that for installation you have the doors made from the panel all oriented in the same direction. So recommended to leave peelcoat on until installed in your space.

Peterman Lumber & StyleLite: What to Do Next

You’ve learned about all the amazing benefits of StyleLite, but what do you do next? Well, that’s where we at Peterman Lumber come in!

Coordinated Materials Program

To help you create modern designs with confidence, Peterman Lumber has brought in new product lines with exact matching products. These perfectly-matched materials integrate a consistent pattern and texture onto any surface. Peterman Lumber is a unique distributor because we are the only distributor that also has capabilities to fabricate Made to Order Cabinet Doors available in 5 Styles that can be delivered along with the raw materials.

Stock Availability

StyleLite is an Australian product. With most distributors, you would have to deal with long lead times. Thankfully, that’s not the case with Peterman Lumber. We have a StyleLite Distribution Center located just 7 miles from our Fontana, C.A., headquarters. This distribution center stocks both the panel and SHAB (laminate).

Both the Panel and SHAB material are available in 4x8ft and 4x10ft options, both of which are optimized for our cabinet and closet fabricators. All StyleLite products start as SHAB (laminate sheets) at 1mm thickness and are then laminated into sheets. That is 43% thicker than any of the competing acrylic products in the market. And that is to ensure a superior finish with no telegraphing or orange peel.

We have quickly become fans of StyleLite because of its superior material and on-trend pattern. But the knowledge and technical support of their team has been the greatest tool for our customers. So, please give your Peterman Lumber rep a call to schedule a visit or stop by your Peterman showroom to see samples of StyleLite today!